Features

- Bioreactor capacity is 30 mL, enabling 5 to 10-fold cell expansion (up to 5 × 10⁷ cells)

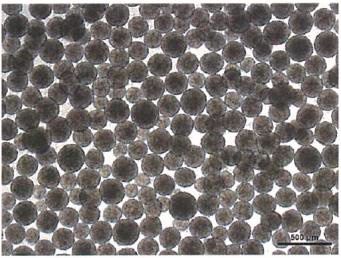

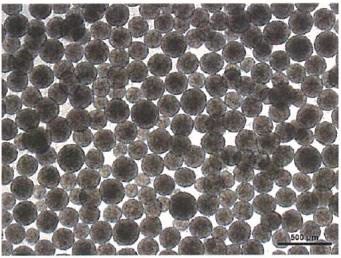

- Typical growth is 200-300 μm spheroids

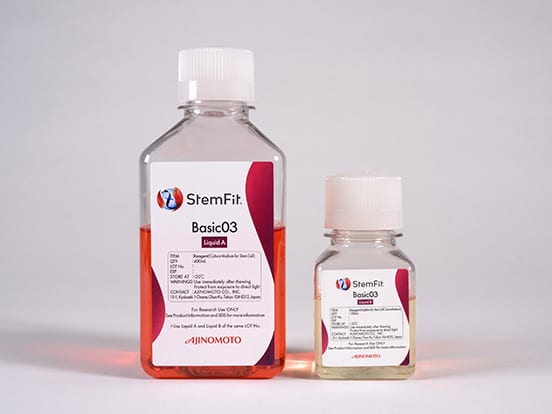

- Compatible with StemFit media and iMatrix-511 recombinant ECM for iPSC culture and expansion

- Bioreactor is made of high density polycarbonate for compatibility with iPS stem cell cultivation

- Vessel interior is surface treated for bio-compatibility

- Polypropylene screw cap 0.2 μm nylon filter allows for passive gas exchange

Product Information Table

| Name | Datasheet | Packsize | Order |

|---|---|---|---|

| ABLE 100 mL Disposable Bioreactor (4 units) | 4 units | View | |

| ABLE 30mL Disposable Bioreactor (6 units) | 6 units | View | |

| ABLE 500 mL Disposable Bioreactor (1 units) | - | 1 units | View |

| ABLE 5mL Disposable Bioreactor (6 units) | - | 6 units | View |

| ABLE Bioreactor Magnetic Stir System Base 30 mL and 100 mL (1 unit) | 1 each | View | |

| ABLE Bioreactor Magnetic Stir System Base 5 mL (1 unit) | - | 1 each | View |

| ABLE Bioreactor Magnetic Stir System Controller and Motor | 1 each | View |

The ABLE 30 mL Disposable Bioreactor

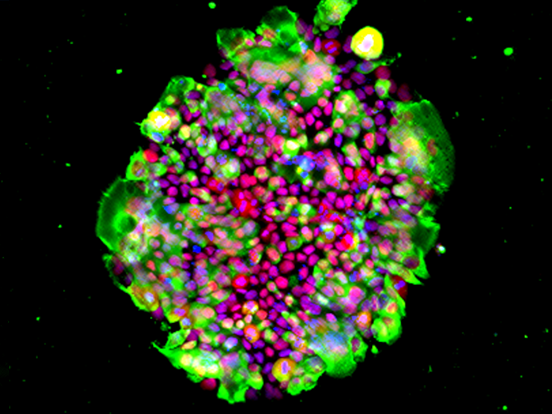

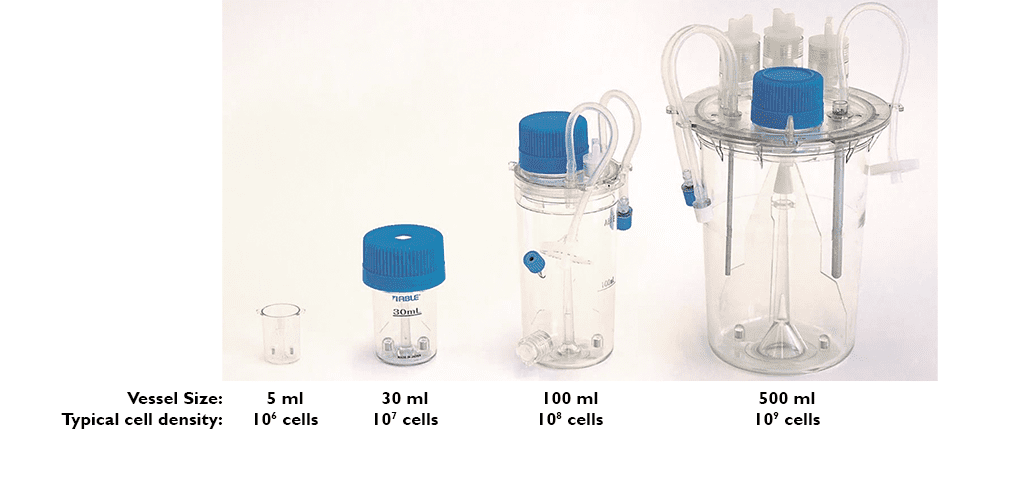

A delta-wing-shaped impeller with a magnet on each blade, located within the bioreactor, provides low shear agitation by laminar flow, encouraging the formation and growth of uniform spheroid cell clusters. The bioreactor allows for the flexibility of using seed stock from single-cell suspensions of iPS stem cells, passaged colony fragments, or mini-spheroids generated from low-adherence cell culture dishes or multi-well plates. Bioreactor vessels of other sizes are available: 5 mL, 100 mL. The 5 mL size requires a different Stirrer Platform. A 500 mL size designed for a stand-alone bioreactor system is also available.

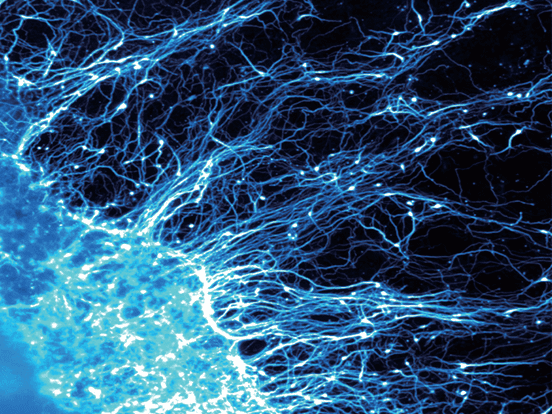

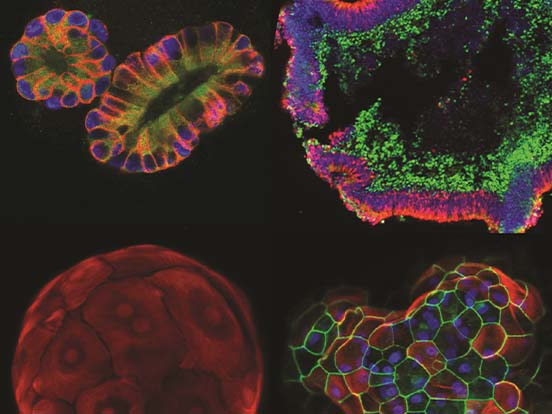

Benefits of Spheroid Culture

The ABLE 30 mL Disposable Bioreactor provides a combination of efficiency, embryoid body formation, cell differentiation, and cost savings. The Bioreactor comes ready-to-use for non-adherent cell growth, eliminating the need for high-priced, high-performance extracellular matrix (ECM) proteins for coating plasticware. One bioreactor enables expansion for up to 5 × 10⁷ cells; approximately equivalent to cell yield from ten 10 cm culture dishes or ten 6-well plates. Ten dishes have approximately 550 cm² of combined surface area.

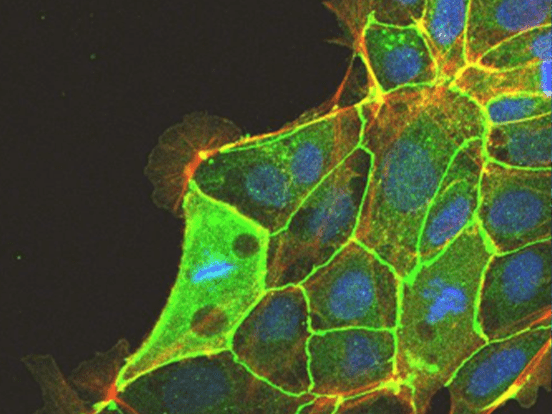

Integration with StemFit Media and iMatrix-511

The ABLE bioreactor seamlessly integrates with StemFit media, a chemically defined stem cell culture media proven to effectively maintain induced pluripotent stem cells (iPSCs) and embryonic stem cells (ESCs) under feeder-free conditions. Human iPSCs, when maintained on iMatrix-511-coated plates along with StemFit media, can be effortlessly harvested and dissociated into single cells. These single cells are then ready for a smooth transition into the ABLE Bioreactor system for large scale and efficient iPSC spheroid culture.

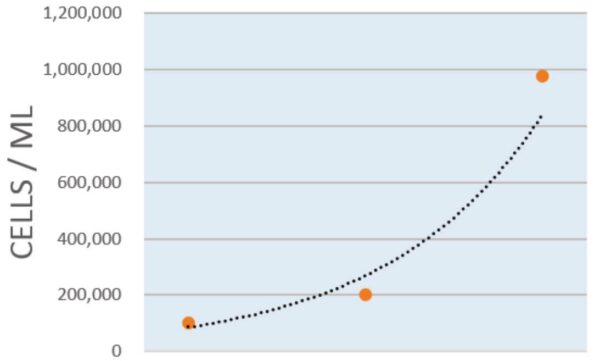

Single cell seeding provides for exponential growth

Human iPS cells (1231A3) were maintained on iMatrix–511–coated plates and grown in StemFit® medium. Cells were harvested and dissociated into single cells using TrypLE Select (ThermoFisher), washed and counted. The single-cells were then seeded at 10⁵ cells/mL in StemFit medium supplemented with 10 μM Y27632 and transferred to the ABLE 30 mL Disposable Bioreactor with constant spinner agitation at 55 rpm. Cells were harvested on day 2 and day 4, and spheroids dispersed by TrypLE Select, stained with trypan blue, and counted.

ABLE Bioreactor Sizes

ABLE System Configuration

The ABLE 3D System has only two components: a six-channel magnetic stirrer platform (30 mL size shown), and an electrical controller and motor unit. The Stirrer Platform is placed inside a CO₂ cell culture incubator allowing the temperature, humidity and gas controls to be passively managed. The controller unit attaches magnetically to the outside of the incubator, and the motor is connected to the Stirrer Platform by a cable.

Controller and motor

Stirrer platform

References

Self-organized yolk sac-like organoids allow for scalable generation of multipotent hematopoietic progenitor cells from induced pluripotent stem cells.

Tamaoki, N. et al. Cell Reports Methods, 2023, 3(4). Citing ABLE Bioreactors with StemFit medium, iMatrix-511 recombinant ECM, StemFit for Differentiation, and CELLBANKER

Adequate taylor couvette flow-mediated shear stress is useful for dissociating human iPS cell-derived cell aggregates.

Matsuura, K. et al. Regenerative Therapy, 2019, 12, 6-13. Citing ABLE Bioreactors with StemFit medium, iMatrix-511 recombinant ECM, and EZSPHERE plates

Fabrication of mouse embryonic stem cell-derived layered cardiac cell sheets using a bioreactor culture system.

Matsuura K. et al. PloS One, 2012, 7(12). Citing ABLE Bioreactors

Creation of human cardiac cell sheets using pluripotent stem cells.

Matsuura K. et al. Biochem Biophy Res Commun, 2012, 425(2). Citing ABLE Bioreactors