Features

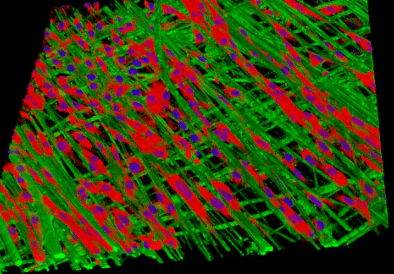

- GMP type I bovine collagen fibers that recapitulates natural strength of native collagen structures

- Induces cellular alignment, migration and elongation

- Capable of supporting 3D cellular growth

Applications

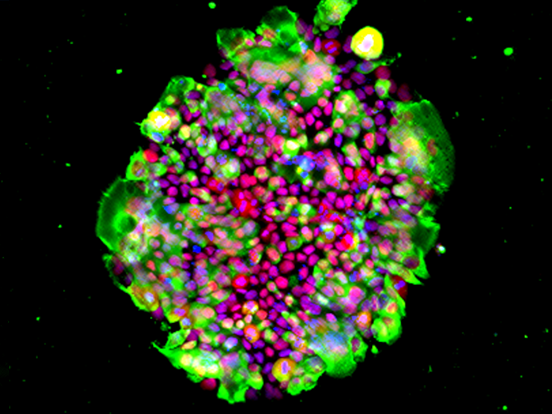

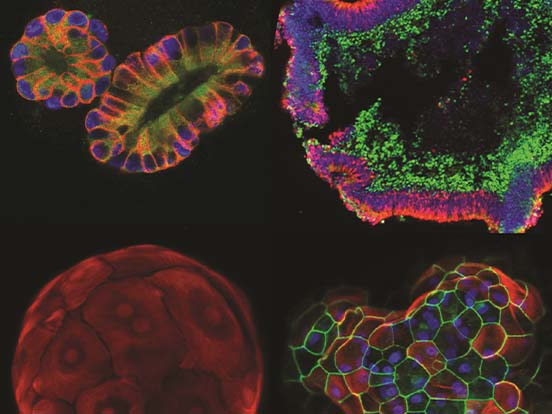

- 3D tissue culture - Physiologically relevant tissue culture environments with high consistency

- 3D bioinks - CollaFibR™ reinforced bioinks that move 3D bioprinting towards the clinic

- Contract tissue engineering - Customized collagen scaffolds to enable tissue model engineering

CollaFibR™ Scaffold for Cell Culture

CollaFibR™ scaffold is a highly consistent collagen fiber matrix. These matrices closely resemble the biomechanical and biochemical properties of natural collagen scaffolds, offering a more accurate representation of in-vivo conditions when studying cell and tissue models.

- Produced using GMP bovine type I collagen, and resemble natural collagen fiber structures

- Degradable with collagenase for easy cell extraction

- User friendly 12-well plate inserts

- Compatible with brightfield, epifluorescence, confocal and live cell microscopy

- UV sterilized and ready to use on receipt

- Available with fluorescent tag

μCollaFibR™- Additive for Bioinks and Hydrogels

μCollaFibR™ are engineered dry-spun 50 μm collagen fibers that increase the shape fidelity and biological relevance of bioprinted constructs. With exceptional chemical stability and ultra-fine 1-2 μm diameters, μCollaFibR™ is universally compatible with bioprinting materials and modalities.

- Produced using GMP bovine type I collagen, and resemble natural collagen fiber structures

- Increases mechanical strength and modulus of hydrogels in extension and compression

- Improves shape retention/durability for at least 28 days in cellular constructs

- Improves cellular viability and functionality within bioprinted cell constructs

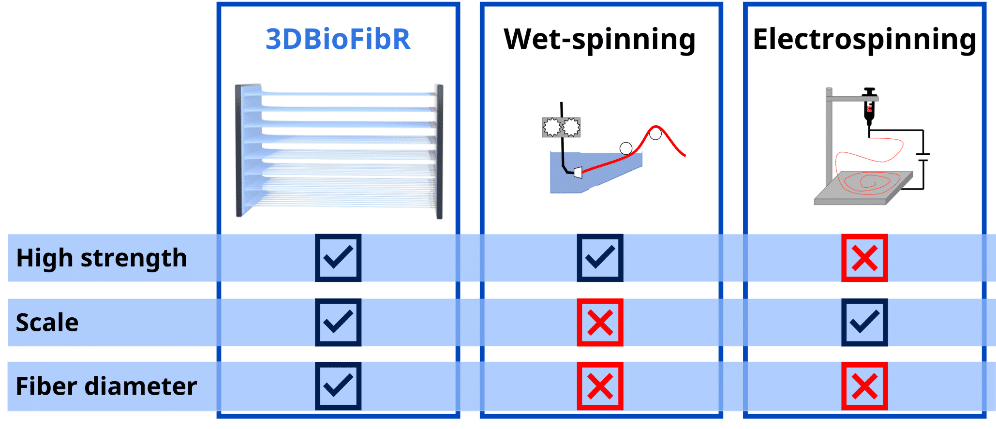

Technology

With over 1000X the throughput of competing technologies, our dry-spinning approach is the first to spin collagen fibers at commercial scales.

By recreating the extensional flows that drive natural self-assembly processes, our fibers closely recapitulate the properties of natural collagen structures.

Strength Profile:

- Patented dry-spinning yields fibers with ultimate tensile strength at 248 MPa, 2-3 times stronger than native tendons.

- Electrospinning's use of volatile solvents and high shear forces limits mechanical and bioactivity features.

Scale:

- Wet spinning produces only 19m of fiber per hour, requiring large lab space. Electrospinning achieves rates of about 1000m per hour.

- Our dry spinning technology can produce 1000m per second.

Fiber Diameter:

- Collagen fibers in the body are typically 1-5 microns in diameter, crucial for cell attachment and directional cues.

- Wet spinning results in fibers with a diameter of 60 microns or more, hindering cell wrapping and directional cues. On the other hand, electrospinning creates fibers that are 0.2 microns or smaller, too fine for cell reliance.

- Dry spinning allows adjustment within the range of 0.2 to 20 microns, optimizing at 1-5 microns for excellent cell attachment, alignment, elongation and migration in tissue engineering.